PLASTISOL HEAT TRANSFERS

Characteristics of Plastisol Heat Transfers:

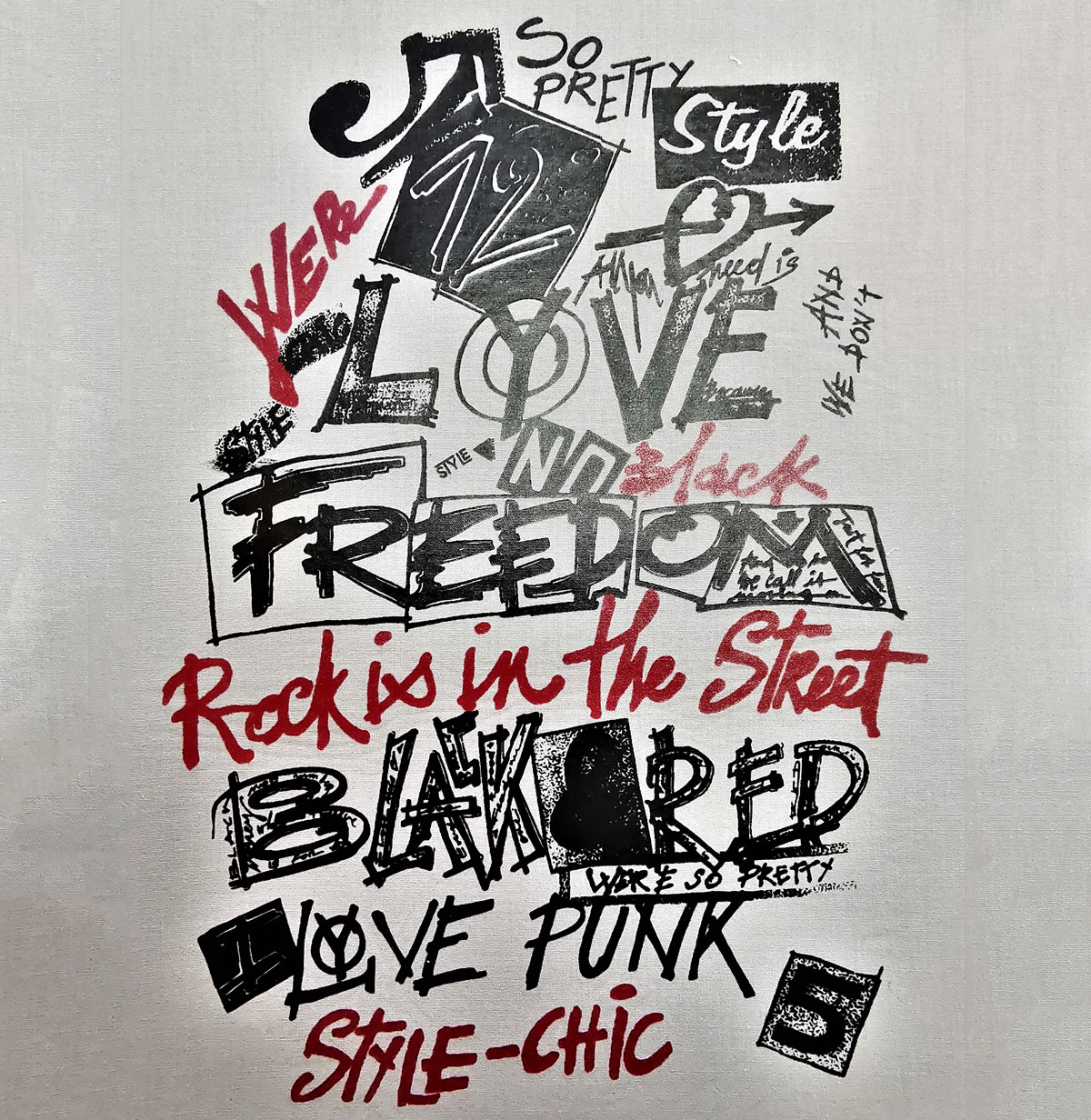

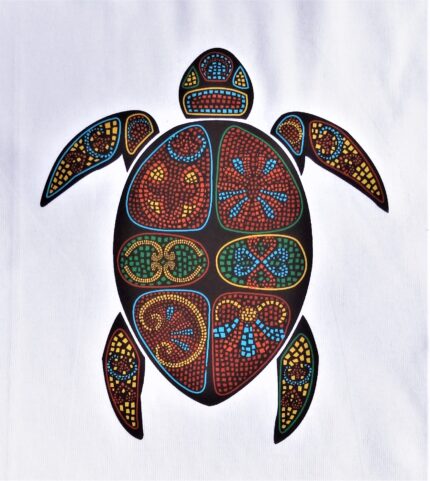

Bright and Opaque Colors: Plastisol inks are highly opaque, which allows them to maintain vibrant and true colors even on dark fabrics. This opacity is particularly advantageous for designs that require strong visual impact and color accuracy.

Glossy or Matte Finish: Depending on the type of plastisol ink, the carrier type and any additives used, the finish can be either glossy or matte.

Versatility: They can be applied to a wide range of fabrics and materials, including cotton, polyester, and blends.

Smooth Texture: The texture of plastisol heat transfers is generally smooth and somewhat plastic-like. This is due to the PVC-based composition of the ink, which lays down a thick layer on the surface of the fabric.

Defined Edges: The transfers typically feature very defined and crisp edges, making them ideal for detailed graphics and text. This precision contributes to the professional quality of the final product.

Durability: Once cured, plastisol transfers are extremely durable. They resist cracking, peeling, and fading, maintaining their appearance through numerous washes and wear.

Convenience: This method allows for the mass production of designs in advance and quick application to garments as needed, making it ideal for fast-paced production environments and for stocking up on popular designs.

Precision: Allows for high-detail printing, which is perfect for intricate designs and sharp, clean lines.

Efficiency: Suitable for both small and large production runs, providing flexibility in order quantity

Άμεσα Διαθέσιμο

Άμεσα Διαθέσιμο Παράδοση 1 έως 3 ημέρες

Παράδοση 1 έως 3 ημέρεςPlastisol heat transfers is the King of heat transfer process. They are used in the apparel industry to apply designs, graphics, or text onto various fabrics. These transfers utilize plastisol ink, which is a particular kind of ink used in screen printing that does not dry at room temperature but instead requires heat to cure and solidify. Plastisol ink is popular due to its durability, color vibrancy, and ease of use. It is the industry standard for fabric screen printing, particularly for heat transfers, due to its unique properties and benefits.

Here’s how plastisol heat transfers work and why they’re popular:

1. Design Creation: The first step involves creating a digital design in a graphic design software like Adobe Illustrator, CorelDRAW, or a similar vector-based program. Vector graphics are preferred for their scalability and clean edges. This design can include logos, text, graphics, or any other imagery that is intended to be transferred onto the substrate.

Design Considerations: Keep in mind the end use of the product. Factors like the fabric type, color, and intended use of the item can influence design elements like color choices and complexity.

2. Ink Preparation: Creating plastisol heat transfers involves preparing a special type of ink used in heat transfer printing on fabrics. Plastisol ink is made primarily of PVC (polyvinyl chloride) resin. It forms a plastic-like layer on the surface of the fabric, which is ideal for durability and vibrant color. It doesn’t air dry; it needs to be heat-cured. Typically, plastisol ink cures at around 160°C, at which point it transforms from a liquid to a solid. Provides excellent coverage, high opacity making it suitable for dark fabrics, also works well on almost all types of fabrics and is excellent for layering colors.

3. Printing on Transfer Carrier: The design is then printed with the screen printing technique onto a special heat transfer paper or directly onto a special clear polyester film using the plastisol inks. This can be done by using solid colors for simple designs or gradients for more complex designs depending on the desired effect.

4. Color Layering: For each of the colors included in the design, a separate screen is prepared. Each screen allows the ink of the specific color to pass through and be transferred to the substrate, which is the transfer paper or a special clear polyester film. The inks are applied in layers, starting with the darkest color and ending with the lightest. The registration of these colors in varying patterns recreates the complex colors and details of the original image.

5. White Layering: In specific cases when the printing of the colors is completed, white ink is printed behind the entire design as a base for two main reasons. One reason is to add extra elasticity to the design, and the second is to provide the brightness needed for the design on dark fabrics.

6. Heat transfer adhesive Layering: In specific cases of temperature-sensitive or difficult, rough and hard fabrics, an additional process may be required, during which a layer of heat transfer adhesive in powder form is added at the bottom of the transfer for better adhesion to the fabric.

7. Curing the Ink and the adhesive: After printing, the ink and the adhesive on the carrier (paper or film) are partially cured (or gelled) using a heat source e.g., an oven, but not fully solidified. This step is crucial because it ensures that both the ink and the adhesive will fully transfer and adhere to the fabric during the heat press process. As a result, this technique guarantees that the plastisol inks form a durable, long-lasting finish on the fabric.

8. Heat Transfer Process: After the design is screen printed onto the carrier (paper or film) and it has dried and fixed in the oven, is then placed adhesive-side down on the garment and pressed using a heat press. The press applies heat and pressure, which causes the activation of the adhesive bonding the design to the fabric. This method allows for the detailed and vibrant designs characteristic of screen printing to be transferred efficiently onto the fabric. The temperature, time and pressure settings are critical and vary based on the fabric type and the specific ink used.

9. Peeling Off the Carrier: After the heat transfer application, the carrier (paper or film) is peeled away while hot or cold (depending on the type of transfer carrier and ink used), leaving the design permanently embedded on the fabric.

10. Final Appearance: The final appearance of plastisol heat transfers on fabric is notable for its vibrant colors and sharp, clean edges, making it highly desirable for various applications in the fashion and promotional industries. The design is also durable and able to withstand washing and wear.

Visual Appeal and Functional Benefits:

Aesthetic Versatility: Plastisol heat transfers can be used to achieve a wide range of graphic styles, from simple text and logos to complex, multi-colored designs. This versatility makes it popular for both artistic and commercial projects.

Consistency: Each transfer maintains consistent quality, which is crucial for producing multiple items with the same design, such as uniforms or retail merchandise.

Customization: Offers excellent customization options, enabling unique designs and limited-edition runs that are appealing in modern apparel markets.

Custom Apparel: Commonly used for creating custom designs on t-shirts, hoodies, and other garments. It's a preferred method for producing vibrant, full-color graphics with a professional finish.

Sportswear: Ideal for jerseys and athletic gear as plastisol transfers can withstand the physical demands and frequent washing required for sports apparel.

Promotional Items: Frequently used for promotional clothing items, such as company uniforms or event giveaways, because the transfers are cost-effective in large quantities.

Fashion Accessories: Also used to decorate bags, hats, shoes, towels, gloves, beanies, scarves, umbrellas and other fabric-based accessories.

Labeling: Employed for labeling garments with brand logos, care instructions, or sizing information because it can create clear, legible text and designs that are long-lasting.

Overall, plastisol heat transfers create a distinctive and lasting visual impact on garments and other fabric products, combining durability with high-quality aesthetic attributes. The final appearance of plastisol heat transfers on fabric is notable for its vibrant colors and sharp, clean edges, making it highly desirable for various applications in the fashion and promotional industries.

Plastisol heat transfers are extensively used for creating customized apparel, promotional items, and for branding purposes in various industries. Plastisol heat transfers are particularly favored in scenarios where product longevity and color vibrancy are crucial, making them a staple in both commercial and craft applications

Για να επιτύχετε το καλύτερο δυνατό αποτέλεσμα και τη μέγιστη ανθεκτικότητα του τυπώματος, ακολουθήστε τα παρακάτω βήματα:

- Πριν την Παραγωγή

Ελέγξτε προσεκτικά τα θερμομεταφερόμενα τυπώματα που παραλάβατε, πριν την εφαρμογή με πρέσα. - Ρύθμιση Θερμοκρασίας – Χρόνου – Πίεσης στην Πρέσα

⚠️Για Τυπώματα χωρίς πρόσθετη κόλλα Θερμομεταφοράς (powder adhesive)

- Για μονόχρωμα η πολύχρωμα σχέδια σε 100% βαμβάκι ή μίγματα βαμβακιού/πολυεστέρα: Ρυθμίστε την θερμοκρασία στους 185-195 °C, τον χρόνο στα 12-15 δευτερόλεπτα και την πίεση στα 5-6 bar (Για χειροκίνητες πρέσες μεγάλη πίεση έτσι ώστε η πρέσα να κλείνει με δυσκολία)

- Για μονόχρωμα η πολύχρωμα σχέδια σε 100% πολυεστέρα: Ρυθμίστε την πρέσα στους 165 – 175 °C, κρατώντας ίδιες όλες τις υπόλοιπες ρυθμίσεις

⚠️Για Τυπώματα με πρόσθετη κόλλα Θερμομεταφοράς (powder adhesive)

- Για μονόχρωμα η πολύχρωμα σχέδια σε 100% βαμβάκι ή μίγματα βαμβακιού/πολυεστέρα: Ρυθμίστε την πρέσα στους 160-170 °C, κρατώντας ίδιες όλες τις υπόλοιπες ρυθμίσεις

- Για μονόχρωμα η πολύχρωμα σχέδια σε 100% πολυεστέρα: Ρυθμίστε την πρέσα στους 150 – 165 °C, κρατώντας ίδιες όλες τις υπόλοιπες ρυθμίσεις

- Προθέρμανση Υφάσματος

Πιέστε το ύφασμα χρησιμοποιώντας στην πρέσα τις ίδιες ρυθμίσεις θερμοκρασίας και πίεσης για 3–5 δευτερόλεπτα πριν την εφαρμογή, ώστε να απομακρυνθεί η υγρασία και να λειάνουν τυχόν ζάρες. - Σωστή Τοποθέτηση

Βεβαιωθείτε ότι η επιφάνεια είναι επίπεδη, καθαρή και λεία. Αποφύγετε ραφές, κουμπιά ή φερμουάρ κάτω από το τύπωμα. - Αφαίρεση Φορέα

Αφαιρέστε τον φορέα όσο το τύπωμα είναι ακόμη ζεστό (θερμή αφαίρεση), η περιμένετε να κρυώσει (ψυχρή αφαίρεση) ανάλογα με τις οδηγίες χρήσης, για άριστη πρόσφυση και ομοιόμορφο φινίρισμα. - Τελική Πρέσα

Για ακόμη μεγαλύτερη αντοχή, επαναλάβετε την πρέσα για 3–5 δευτερόλεπτα με τις ίδιες ακριβώς ρυθμίσεις χρησιμοποιώντας χαρτί σιλικόνης ή φύλλο τεφλόν επάνω στο τύπωμα. - Δοκιμή Πριν την Παραγωγή

Πραγματοποιήστε πάντα δοκιμή σε κάθε νέο τύπο υφάσματος η τυπώματος πριν προχωρήσετε σε πλήρη παραγωγή, ώστε να εξασφαλιστεί η σωστή πρόσφυση και το ιδανικό αποτέλεσμα.

⚠️Σημείωση: Οι προτεινόμενες ρυθμίσεις χρόνου, θερμοκρασίας και πίεσης βασίζονται στις θερμοκολλητικές πρέσες που χρησιμοποιούμε στην Printto. Οι τιμές αυτές μπορεί να διαφέρουν ελαφρώς σε άλλες πρέσες θερμομεταφοράς.

Οι ρυθμίσεις της δικής σας πρέσας (θερμοκρασία, χρόνος και πίεση) ενδέχεται να χρειάζονται μικρή προσαρμογή, ανάλογα με τον τύπο του υφάσματος, τον τύπο της πρέσας (χειροκίνητη ή αυτόματη), καθώς και το υλικό και το πάχος του υποστρώματος που χρησιμοποιείται στην κάτω πλάκα (π.χ. σιλικόνη, τσόχα κ.λπ.). Μικρές διαφοροποιήσεις, όπως αύξηση ή μείωση της θερμοκρασίας, της πίεσης ή του χρόνου εφαρμογής, μπορεί να είναι απαραίτητες για τη βελτίωση της πρόσφυσης και της συνολικής ποιότητας του αποτελέσματος.

⚠️Συνιστάται πάντα να πραγματοποιείται δοκιμή σε δείγμα πριν από την κύρια παραγωγή, ώστε να εξασφαλίζεται το ιδανικό φινίρισμα και η μέγιστη αντοχή του τυπώματος.

| Τεχνικές Προδιαγραφές | Τυπική Ρύθμιση / Σημειώσεις |

| Συνιστώμενη Θερμοκρασία Πρέσας | • ΧΩΡΙΣ πρόσθετη κόλλα θερμομεταφοράς (powder adhesive): 185–195 °C (βαμβάκι / μίγματα) 165–175 °C (πολυεστέρας) • ΜΕ πρόσθετη κόλλα θερμομεταφοράς (powder adhesive): |

| Χρόνος Πίεσης | 12 – 15 δευτερόλεπτα (ανάλογα με το ύφασμα & το πάχος του μελανιού) |

| Πίεση | 5–6 bar για αυτόματες πρέσες. Για χειροκίνητες πρέσες: μεσαία έως μεγάλη πίεση, με πλήρη και ομοιόμορφη επαφή σε όλη την επιφάνεια (η πρέσα να κλείνει με αισθητή αντίσταση). |

| Τρόπος Αφαίρεσης Φορέα | Ψυχρή αφαίρεση (εκτός αν αναφέρεται διαφορετικά για το συγκεκριμένο προϊόν) |

| Αντοχή στο Πλύσιμο | Δοκιμασμένα σε πάνω από 50 κύκλους πλυσίματος οικιακής χρήσης, υπό σωστές συνθήκες εφαρμογής |

| Διαστάσεις Φύλλου Εκτύπωσης | 50 Χ 70 cm (εκτυπώσιμη επιφάνεια 48 Χ 68 cm) |

| Ελάχιστη Ποσότητα Παραγγελίας | 1 πλήρες φύλλο 50 Χ 70 cm ανά χρωματικό συνδυασμό |

| Τύπος Μελανιού | Πλάστισολ (χωρίς φθαλικές ενώσεις – phthalate-free) |

| Σημείωση | Οι παραπάνω ρυθμίσεις αποτελούν γενικές οδηγίες. Συνιστάται πάντα δοκιμή στο συγκεκριμένο ύφασμα και σχέδιο σας. Για εξειδικευμένη τεχνική υποστήριξη, επικοινωνήστε με την ομάδα παραγωγής της Printto. |

Για να διατηρήσετε τη μέγιστη ανθεκτικότητα και εμφάνιση των θερμομεταφερόμενων τυπωμάτων της Printto, ακολουθήστε προσεκτικά τις παρακάτω οδηγίες:

- Πλύσιμο από την Ανάποδη Πλευρά του Ρούχου

Γυρίστε το ρούχο ανάποδα (το μέσα έξω) πριν το πλύσιμο, ώστε να προστατεύεται το τύπωμα από τριβές και μηχανική φθορά. - Πλύσιμο σε Χαμηλή Θερμοκρασία

Πλύνετε στο πλυντήριο με κρύο ή χλιαρό νερό (έως μέγιστο 40 °C) σε ήπιο πρόγραμμα, αποφεύγοντας το δυνατό στύψιμο. - Ήπια Απορρυπαντικά – Όχι Λευκαντικά

Αποφύγετε τη χρήση λευκαντικών, ισχυρών απορρυπαντικών ή προσθέτων που περιέχουν ένζυμα ή χλώριο. - Στέγνωμα

Στεγνώστε σε χαμηλή θερμοκρασία ή αφήστε το ρούχο να στεγνώσει φυσικά σε σκιερό μέρος. Μην τοποθετείτε το ρούχο σε άμεση επαφή με θερμαντικά σώματα ή απευθείας στον ήλιο. - Σιδέρωμα

Μην σιδερώνετε ποτέ απευθείας πάνω στο τύπωμα. Εάν απαιτείται, σιδερώστε το ρούχο από την ανάποδη πλευρά ή τοποθετήστε ένα λεπτό ύφασμα / χαρτί σιλικόνης ανάμεσα στο σίδερο και την επιφάνεια. - Αποφυγή Στεγνού Καθαρισμού

Μην χρησιμοποιείτε υπηρεσίες στεγνού καθαρισμού (dry-cleaning), καθώς τα χημικά διαλύματα μπορεί να αλλοιώσουν το μελάνι και την κόλλα του τυπώματος.

Διαχείριση & Αποθήκευση των Προϊόντων μας

Για να διατηρείτε σταθερή ποιότητα και μέγιστη ισχύ συγκόλλησης, αποθηκεύστε και χειριστείτε τα θερμομεταφερόμενα τυπώματα σωστά:

Συνθήκες Αποθήκευσης

• Θερμοκρασία: 18–24°C

• Υγρασία: 40–60%

• Μακριά από άμεσο ήλιο και πηγές θερμότητας

• Σε καθαρό δροσερό, ξηρό περιβάλλον, με προστασία από σκόνη και υγρασία

Τρόπος Αποθήκευσης

• Φυλάσσετε τα τυπώματα επίπεδα, ώστε να μην παραμορφώνονται ή τσαλακώνονται

• Τοποθετήστε προστατευτικό φύλλο (π.χ. χαρτί σιλικόνης ή kraft) ανάμεσα σε φύλλα/τυπώματα

• Κρατήστε τα σε κλειστή συσκευασία ή σε σακουλάκια με κλείσιμο zip για επιπλέον προστασία

Χειρισμός

• Χειρίζεστε με καθαρά, στεγνά χέρια και πιάστε από τις άκρες

• Αποφεύγετε λυγίσματα ή διπλώματα που μπορεί να δημιουργήσουν μόνιμες τσακίσεις

• Σε μεγάλα σχέδια, στηρίζετε ολόκληρη την επιφάνεια κατά τη μετακίνηση

Μεταφορά

• Μεταφέρετε επίπεδα ή σε χαλαρό ρολό (αν απαιτείται), χωρίς πίεση

• Μην τοποθετείτε βάρος επάνω στα θερμομεταφερόμενα τυπώματα

Διάρκεια Ζωής

Για καλύτερο αποτέλεσμα, συνιστάται χρήση εντός 6–12 μηνών. Σε παλαιότερα τυπώματα, προτείνεται δοκιμαστική εφαρμογή πριν από παραγωγή.

Η Printto πραγματοποιεί αποστολές σε όλη την Ελλάδα και το εξωτερικό, με αξιόπιστους συνεργάτες μεταφοράς και πλήρη παρακολούθηση αποστολής (tracking).

Τρόποι Αποστολής

Οι αποστολές εκτελούνται μέσω συνεργαζόμενων εταιρειών courier (ACS, Γενική Ταχυδρομική, ΕΛΤΑ Courier, IDP) ή μεταφορικής εταιρείας της επιλογής σας.

Υπάρχει επίσης δυνατότητα χρήσης δικού σας λογαριασμού ταχυμεταφοράς, κατόπιν συνεννόησης.

Χρόνοι Παράδοσης

Εντός Ελλάδας, η τυπική παράδοση πραγματοποιείται συνήθως σε 1–3 εργάσιμες ημέρες από την αποστολή.

Για επείγουσες παραγγελίες, παρέχεται δυνατότητα εξπρές αποστολής.

Ογκώδεις ή Μεγάλες Παραγγελίες

Για χονδρικές ή μεγάλου όγκου αποστολές, διατίθεται μεταφορά σε παλέτα ή ειδική μεταφορική λύση, κατόπιν αιτήματος.

Παραλαβή από τις Εγκαταστάσεις μας

Υπάρχει δυνατότητα παραλαβής από τις εγκαταστάσεις της Printto στην Περαία Δήμου Θερμαϊκού, κατόπιν συνεννόησης.

Ασφαλής Συσκευασία

Όλες οι παραγγελίες συσκευάζονται με τρόπο που διασφαλίζει την προστασία των θερμομεταφερόμενων τυπωμάτων κατά τη μεταφορά.

Έξοδα Αποστολής

Τα έξοδα αποστολής υπολογίζονται ανάλογα με τον όγκο, το βάρος και τον προορισμό της παραγγελίας και επιβαρύνουν τον πελάτη, εκτός εάν έχει συμφωνηθεί διαφορετικά εξαρχής.